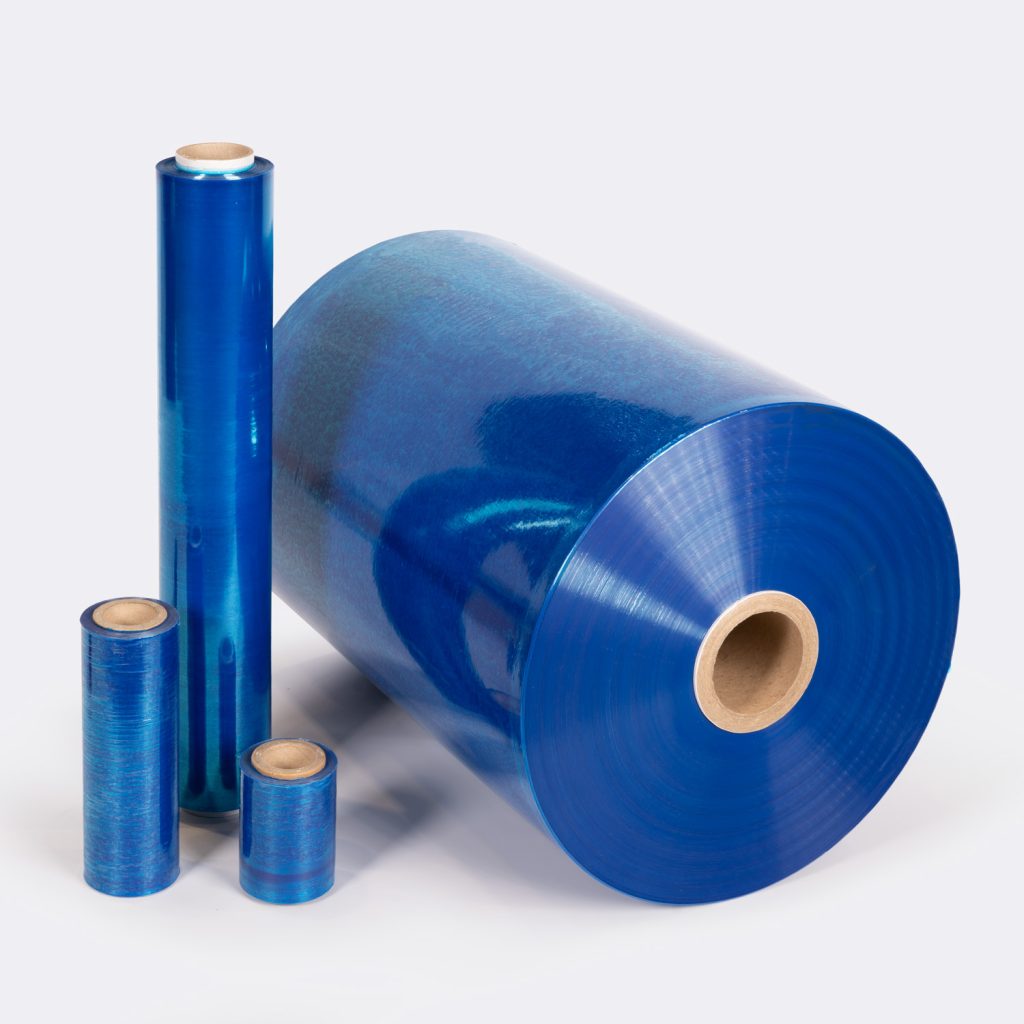

Lipni klijavimo juosta

Gaminame ir tiekiame pačias įvairiausias lipnias klijavimo juostas – su spauda, įvairių spalvų ir pločių.

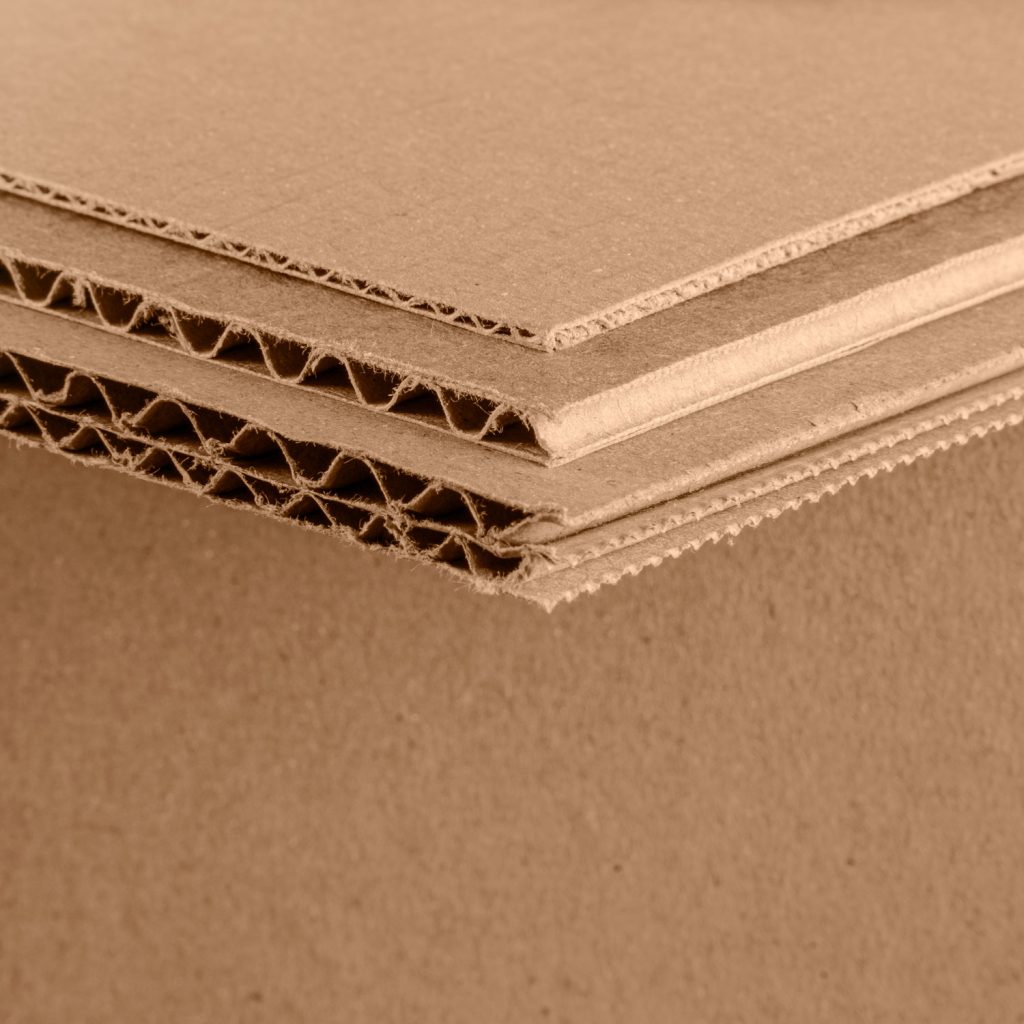

Gofro kartonas

Įvairiausių rūšių gofro kartono gamyba ir tiekimas.

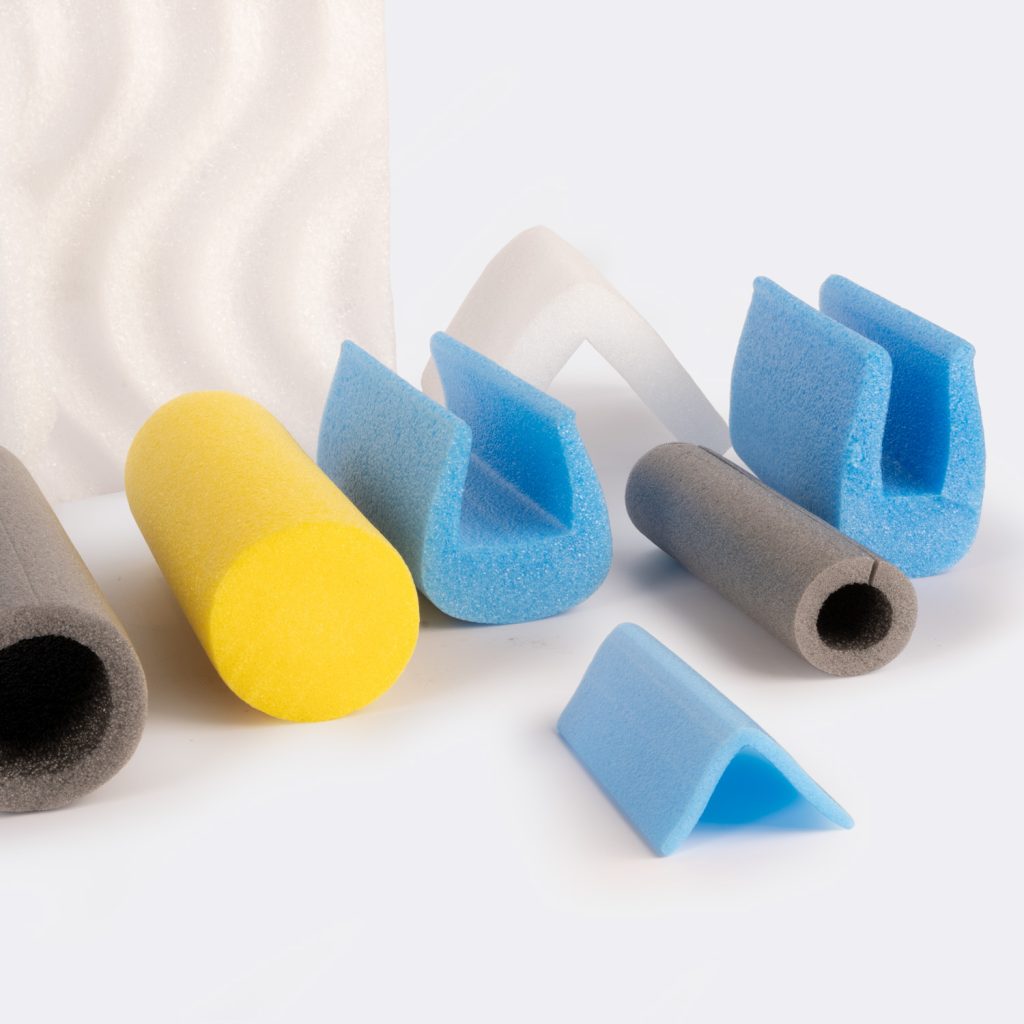

Burbulinė-pūsta plėvelė

Visų parametrų ir paskirties burbulinės-pūstos plėvelės produktai.

Maišai

Standartiniai ir specialių parametrų maišai ir oro maišai.